Tannery Machines' Manufacturer!

Tannery Machines' Manufacturer!

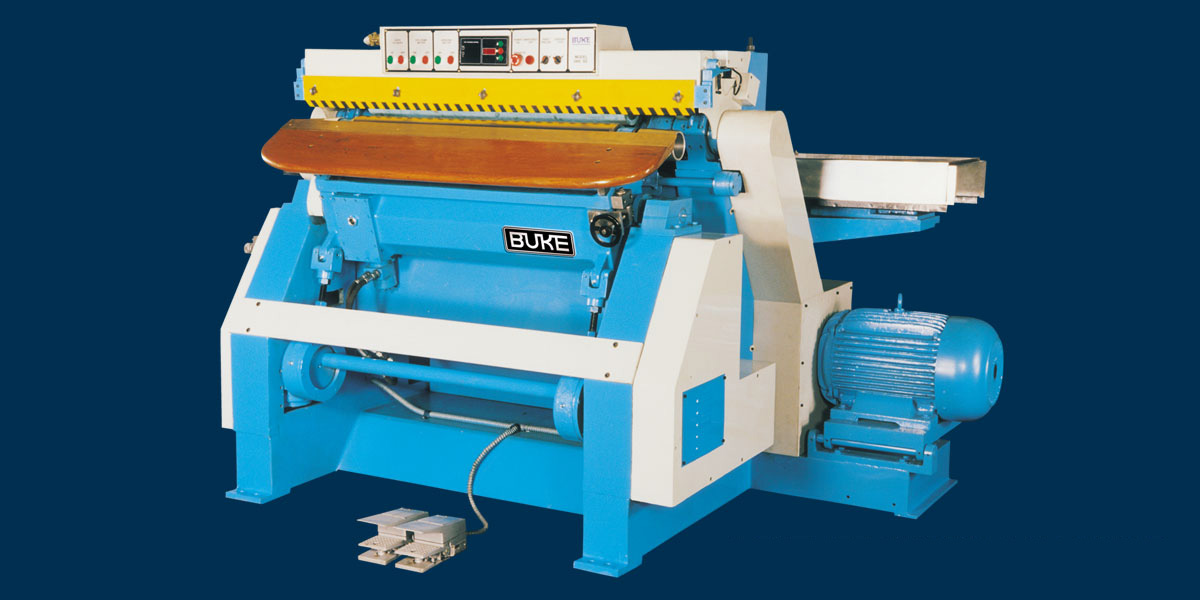

Bharat Udyog is manufacturing the Shaving machines in the working widths of 500 mm to 1500 mm. After studying carefully the requirements of the various tanners Bharat Udyog has developed BUKE 1000 mm Shaving Machine for shaving of all types leathers in wet, dry and also blue chrome condition. Its simplicity of operation with extremely rigid construction enables the machine to give high production output with desired quality levels. Decades of experience backed by sound technology and prompt after sales service ensures trouble-free operation and highly productive machine with superior performance, quality and longer life.

The complete frame structure of the machine is made of graded cast iron with sufficiently thick and well ribbed section. This assures extreme rigidly of construction which eliminates any chance of vibration mark on leather even under heaviest cut.

The Knife Cylinder is made from high strength forged steel and rotates in a heavy duty ball bearings with grease lubrication and dynamically balanced to ensure chatter free operation. The standard cylinder is fitted with 10 LH and 10 RH blades.

The feed roller is driven by a hydraulic motor with reduction gear box and feed speed can vary from 0 to 20 meters/min. The opening and closing of feed roller is accomplished by precision cam operated mechanism driven by hydraulic cylinder which enables accurate leather thickness even under heaviest cut load. All the links and mechanisms involved are having ball bearings / roller bearings at the joints ensuring friction free movements reducing wear & tear resulting in prolonged machine life.

b) Due to the flywheel effect of the main shaft at high speed, the power required is less than equivalent machines. This leads to low power consumption at the same output.

The facility of grip roller enables easy feeding of leather and avoid'wastage of leathers because of cutting at folds. Also it reduces the operator fatigue to a great extent resulting in more output. The machine is provided with taper setting attachment to take care of any uneven thickness after shaving the leathers to its full span.

The machine is fitted an electronic fine thickness adjustments device which enables the initial, setting to be varied in steps of 0.1 mm.

The grinder travels on a heavy duty slide with an electromechanical drive. This enables perfect grinding of knives. The feeding of grinding wheel in knives is automatic and no human intervention is required, reducing time required for grinding.

All electric motors are provided with overload relays. Grinding feed can not start until the grinding motor is ON. A safety device is provided near the Knife Cylinder which will stop the machine if the operator touches the same accidently. Sheet metal guards are provided whenever necessary.

| MODEL | 800 H | 1000 H |

|---|---|---|

| Working Width | 800 MM | 1000 MM |

| Knife cylinder motor | 15 HP / 25 HP* | 20 HP / 30 HP* |

| Hydraulic Pump motor | 3 HP | 4 HP KW |

| Grinding motor | 1 HP | 1 HP |

| Speed | 0 - 20 mtrs/min | 0 - 20 mtrs/min |

| Attendance | One operator | One operator |

| Floor space | 2400 x 1500 mm | 2700 x 1500mm |

| Net weight | 2500 Kgs. (approx) | 3500 Kgs. (approx) |

| *Selection as per shaving requirements |

Due to constant research and development, specifications and features are subject to change without notice.