Tannery Machines' Manufacturer!

Tannery Machines' Manufacturer!

BUKE Hydro pneumatic throughfeed buffing machines are designed to meet the stringent quality requirements of modern tanning industry. The machines are suitable for buffing of leather on both the grain and flesh sides. The machines are robust in construction and easy to operate eventhough they are sensitive and accurate. Details of experience in manufacturing tannery machinery and sound technology backed up by prompt after sales service will guarantee a highly productive machine with superior quality and longer life.

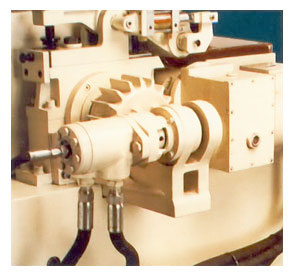

The frame unit is extremely rigid and is constructed of two side frames of graded Cast Iron joined by a fabricated steel base and two support beams. This frame unit forms a rigid structure for mounting of all the assemblies over it and eliminates any chance of vibration.

The buffing cylinder used in this machine is made out of high strength aluminium alloy. It is dynamically balanced on Computerised Balancing machine to avoid any vibration or chatter marks on the leather. Morever it is fitted in precision and sturdy roller bearings to give longer service life. The mechanism in the buffing cylinder is so designed that changing the buffing paper is an easy task for the operator.

The machine is fitted with Cylinder Oscillating Mechanism for better buffing result. The cylinder oscillation mechanism is driven by hydraulic motor and the frequency of oscillation is infinitely variable from 0 to 225 Osc./ min. accordingly to the requirements of the buffing operation.

The feed roller is coated with special soft rubber to give better finish on the leather. The feed roller is driven hydraulically using a reduction gear box. Feed speed can be infinitely varied in the range of 0 -25 m /min. Opening and closing of the feed roller is achieved pneumatically ensuring fast operation resulting in more productivity..

The machine is fitted with a pneumatically operated hide blade to hold the leather at the end of buffing operation. This device ensures buffing of total AREA of the leather.

The Skin Conveyor fitted in the machine can be moved in both the directions i.e. forward and backward enabling the collection of processed skins either on the frontside or backside of the machine. The speed of the Skin Conveyor is infinitely variable from 5 m/min. to 30 m/min. and can be set in accordance with the speed of the buffing operation. The provision of Skin Conveyor facilitates the machine attach to dedusting machine forming a continuous processing.

| MODEL | BF 130 | BF 180 |

|---|---|---|

| Working Width | 1300 mm | 1800 mm |

| Buffing Cylinder Motor | 15 K.W. | 18.57 K.W. |

| Hy. Pump Motor | 2.20 K.W. | 2.2 K.W. |

| Conveyor Motor | 0.75 K.W. | 0.75 K.W. |

| Exhaust Motor | 3.75 K.W. | 3.75 K.W. |

| Feed Speed | 0 to 25 m/min. | 0 to 25 m/min. |

| Conveyor Speed | 5 to 25 m/min. | 5 to 25 m/min. |

| Oscillation Speed Of Buffing Cylinder |

0 to 225 Ocs./min. | 0 to 225 Ocs./min. |

| Attendance | 1 or 2 Operators | 1 or 2 Operators |

Due to constant research and development, specifications and features are subject to change without notice.